The inland navigation sector has a significant potential to reduce energy demand, carbon intensity, and air pollutant emissions, and numerous technologies are already available to achieve this objective. While most of them are partly incorporated in new vessels, the potential for their implementation in the existing fleet is limited as it requires a significant intervention in the existing structure. Nevertheless, the greening transformation of the inland fleet cannot wait for the next generation of vessels to be built.

The objective of the SYNERGETICS work package 3 Demonstration is to validate the viability of retrofitting solutions for decarbonization and pollutant emission reduction for different coastal and inland navigation vessels in operation. SYNERGETICS subtask 3.3.2 addresses the greening potential of hydrodynamic improvements of ship’s hull and appendages.

One possible innovative solution consists of the replacement of the entire aft section of an existing ship with an optimized one; this way, approximately 80% of the existing ship structure and arrangement is preserved, while the ship can be brought up to the latest state of development. In addition, the ship downtime is drastically reduced in comparison to a conversion.

The possible benefits include:

- A conversion from single-screw to multi-screw propulsion or vice versa;

- Reduced power demand due to the aft ship optimization based on detailed operational profiles by means of numerical and experimental methods;

- Replacement of the classic propeller tunnel with a so-called flex tunnel, which reduces the minimum draught (increased resilience in low-water periods) and the power demand at larger draughts;

- A coordinated design of the duct, propeller, rudder, and ventilation prevention plate arrangement, which improves the aft flow. This reduces power demand and vibration excitation, and thus sound emissions;

- Cost-effective implementation of exhaust gas after-treatment (which otherwise often could not be done due to the heat emitted, and the space required);

- Cost-effective retrofit to alternative (hybrid) propulsion systems (hydrogen, methanol or LNG).

A possible reduction of energy demand due to hydrodynamically optimized interaction of hull, propulsor and waterway only, is already between 10% and 40%. With modern engines, (partial) electrification, and sustainable energy carriers the environmental performance can be further improved.

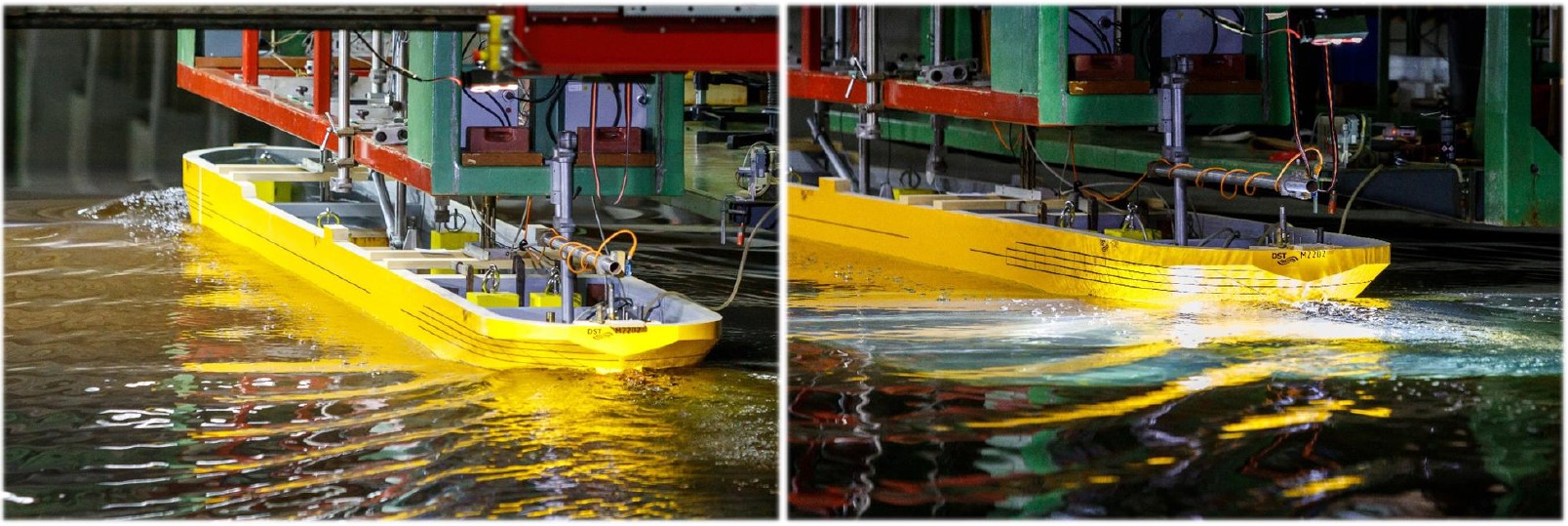

Within the scope of SYNERGETICS work package 3, the model-scale demonstration of and a complete analysis of the benefits of aft-ship replacement will be performed using the dry cargo motor vessel “Ernst Kramer” from the fleet of the German shipping company Rhenus, which actively supports SYNERGETICS. This 50-year-old vessel has an overall length of 105 m, a beam of 9.5 m, a draft of 3.22 m, and 1170kW of installed engine power. Additionally, it is equipped with a bow thruster by Verhaar, which has a power rating of 315 kW. Based on the data reported in the CCNR study on energy transition towards a zero-emission inland navigation sector, the potential impact of retrofit of the dry cargo motor vessels with length between 80 m and 109 m can be exceptionally high, considering their CO2, NOx, and PM emissions.

The initial model tests were performed at DST – Development Centre for Ship Technology and Transport Systems to establish the baseline performance of the ship. In the next phase, the aft of the ship will be redesigned and optimized by means of CFD. The results will be verified in the subsequent model test campaign. Finally, business analyses will be carried out in the validation process, demonstrating the economic viability of this solution.

Exclusive footage of the model tests is available here.